Power-to-Methan pilot at OST

HEPP (High Efficiency Power-to-Methane Pilot)

Source: OST (Eastern Switzerland University of Applied Sciences) | IET Institute for Energy Technology

Power supply 2050

Approximately 65% of Switzerland's energy consumption is provided by chemical energy sources. These energy sources are usually derived from fossil fuels. Through their combustion, carbon dioxide is released into the earth's atmosphere. In order to achieve the world's climate goals, these emissions are to be reduced.

This is where the IET (Institut für Energietechnik) at the OST (Eastern Switzerland University of Applied Sciences) in Rapperswil comes in.

Carbon cycle

Power-to-methane technology is used to produce a new chemical substance, synthetic methane, from electricity, water and carbon dioxide. The special feature of this process is that recycled carbon dioxide is used, which is obtained, for example from the ambient air or from a biogas plant. Thus, when the methane is burned, no additional carbon dioxide is emitted, but the recycled one. In technical jargon, this process is referred to as a closed carbon cycle.

Source: OST (Eastern Switzerland University of Applied Sciences) | IET Institute for Energy Technology

Principle of the research plant

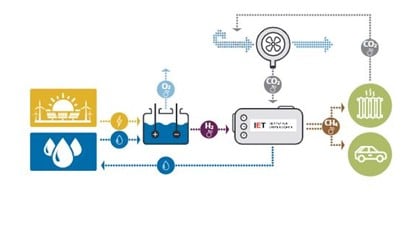

The diagram shows the principle of power-to-methane production in this research plant: a photovoltaic system supplies electricity. With this renewable electricity, water (H2O) is split into hydrogen (H2) and oxygen (O2) by electrolysis. The recycled carbon dioxide (CO2) is extracted from the ambient air using a CO2 separator. The two substances hydrogen (H2) and carbon dioxide (CO2) are converted to methane (CH4) in a reactor. This synthetically produced methane can be obtained directly from the integrated natural gas filling station or is fed into the local natural gas grid.

HEPP: High Efficiency Power-to-Methane Pilot

This container plant was built for the HEPP and Pentagon projects. In these projects, technical innovations are being researched, e.g. the integration of a high-temperature electrolysis and heat management into the power-to-methane technology. These innovations will increase the efficiency of the technology from 55% to approximately 70%. With the increased efficiency, the price and environmental impact of the methane produced are reduced. Thus, with the new research results, the technology can be helped to achieve a breakthrough.

Swagelok Switzerland

Our idealism, our support of the CH energy targets 2050 and or our conviction of the necessity of PtG plants were just some of the many motivations for us to support the HEPP High Efficiency Power-to-Methane project.

Our Swagelok products are used for plant process control. Pneumatically or electrically actuated Swagelok valves enable end-to-end plant automation. High efficiency electrolysis is associated with very high process temperatures, which require the use of Swagelok steam series valves.

The following Swagelok products are key components of the HEPP power-to-gas system:

- Swagelok tube fittings, orifice plates, flange adapters

- Thin-walled Tubing

- 40 and 60 series ball valves (manually and pneumatically actuated); S60P steam series for high temperatures

- Needle valves series 1 as regulating valves (manual), resp. with servo motor as regulating valves

- Low flow metering valves series M (manual)

- Check valves series C + CH

- Relief valves RL + R3A

- Safety relief valves PRV

- Pressure regulators series KPR

- Changeover manifold series KPR

- Filters

- Pressure gauge

- Flowmeter

Further information and reports on the High Efficiency Power-to-Methane Project (HEPP)

-

HEPP: High Efficiency Power-to-Methane Pilot (IET Institute for Energy Technology)

-

Forschung & Entwicklung an der HEPP-Analge (IET Institute for Energy Technology)

- Hochtemperatur soll Power-to-Gas befeuern (energate messenger.ch)

- Power-to-Product als künftige Rohstoffquelle (Bulletin.ch)

Do you have questions about Swagelok services or products? We look forward to hearing from you.

info@arborag.ch | +41 56 485 61 61