Calibrating H2 fuel pumps

Calibrated hydrogen fuel pumps for the mobility of the future

In order to refuel fuel cell cars with hydrogen, a network of filling stations is required in addition to the corresponding vehicles. This is being built at high pressure in Switzerland and the creation of a nationwide hydrogen filling station network and the associated supply is planned for the coming years.

With a new system, the Federal Institute for Metrology (METAS) has developed the metrological basis to be able to calibrate or check the fuel pumps on site.

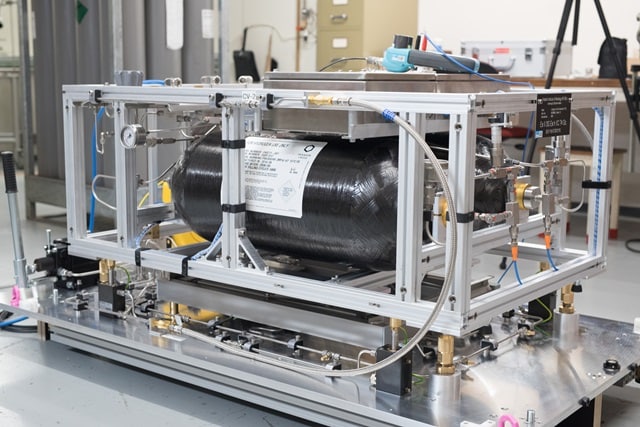

Metas hydrogen test and calibration facility

Swagelok Switzerland was allowed to supply METAS with tube fittings, couplings, check and regulating valves, pressure gauges and metal hoses for the H2 measuring system.

Produce hydrogen on site

Long ranges and short refueling times, in the range of minutes, are reminiscent of the comfort of conventional vehicles. With the help of electrolysis systems directly on site, which require little space, the fuel gas could be produced on site and the effort for distribution to the consumers is eliminated. Like conventional systems, H2 filling stations will also have to meet metrological requirements in the future and be able to be traceably calibrated. For this purpose, METAS developed a mobile, primary gravimetric measuring system. Instead of a vehicle, this is refueled according to a standardized SAE (Society of Automotive Engineers) process. The internationally recognized and used SAE protocols aim to protect the pressure tanks against excess pressure and excess temperature. Because hydrogen gas has the physical property that it heats up at temperatures of over –60 ° C during the expansion process. In addition to the heat of compression, considerable temperature rises can occur quickly. This is the reason why hydrogen has to be pre-cooled to approx. –40 ° C before entering the pressure tanks in order to keep the refueling times short.

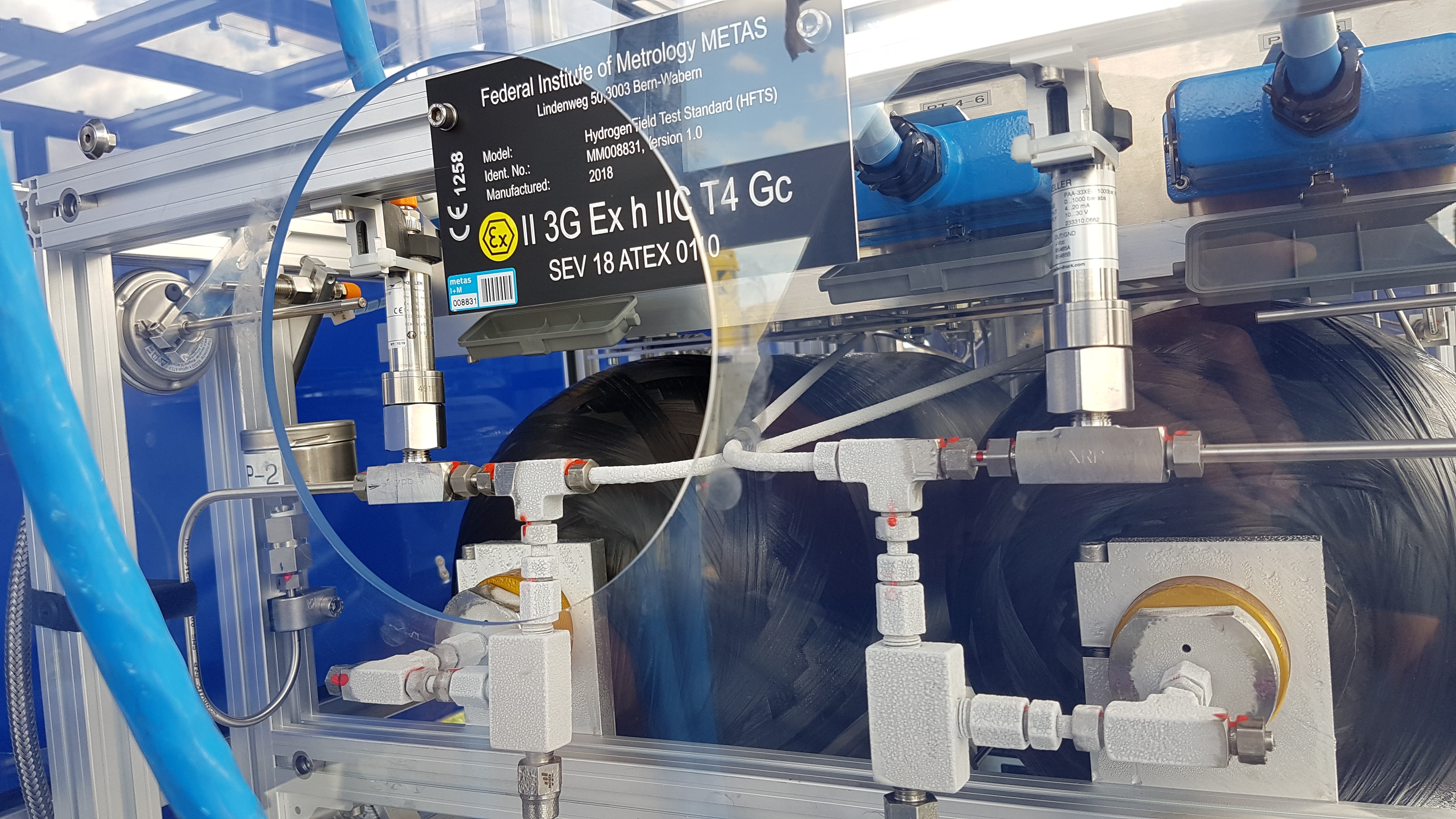

The temperature and pressure conditions in the two carbon fiber pressure tanks, each with a capacity of 36 liters, of the METAS test system are continuously measured and monitored electronically. For the construction of the test system, the quick-to-install and vibration-proof FK tube fitting as well as compatible tubes from Swagelok were used, which withstand a mean pressure of up to 1378 bar, while the measuring system is designed for a maximum filling pressure of 875 bar. High pressure regulating valves also help the user to operate the test system easily and safely.

Because various influencing factors have to be excluded or taken into account, this measurement is complex in practice. Temperature or pressure-related volume changes as well as changes in the atmospheric ambient conditions such as pressure, temperature and air humidity and the associated changes in lift, wind, changing surface temperatures or condensation deposits can also falsify the measurement results.

To inert the system, including, pressure tank, Swagelok full metal hoses were chosen.

Swagelok custom solution

This measuring system has a uncertainty of 3 grams (with k = 2). This enables METAS to carry out calibrations, tests or type tests of hydrogen pumps with the required accuracy. At the end of each individual measurement, the entire content of the pressure tanks must be released into the atmosphere in a controlled manner. Swagelok full metal hoses, check valves and quick-release couplings with free flow are in use for this process step.

The system is ATEX Zone 2 certified. This required close cooperation with SUVA and Eurofins (ignition hazard assessment, conformity test of ATEX regulations, issuing of certification documents).

Successful tests finished, further development planned

Several measurements from METAS a.o. at Empa's H2 filling station were successful, but very time-consuming and complex and therefore expensive to transport. A possible solution for the future could be the development of a «measuring case», which contains a sufficiently characterized transfer standard.

To see the complete hydrogen compatible productlist, click here.

Do you have questions on our services or products? Contact us via E-Mail info@arborag.ch | Tel. +41 56 485 61 61